Waterproofing

Guide and Information

Guide to waterproofing inside and out

For interiors and exteriors in new and old buildings alike

Most waterproofing issues manifest themselves in the interior of the building rather than the exterior.

Most damage caused to the fabric of a building is usually caused by moisture or water at the heart of the problem. This occurs from the roof right down to the basement or cellar. So how can it be stopped and protected? You’ve guessed it – waterproofing!

What is waterproofing?

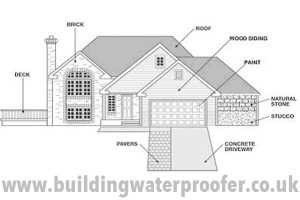

Waterproofing is the creation of an impervious barrier over the surfaces of your building, outdoor surface or material to stop water getting in. This may be on roofs, walls, masonry, wooden cladding, basements, cellars foundations, driveways, patios, decks etc.

See out Find Waterproofing Products page to see visually what can be waterproofed.

Types of waterproofing products

Cementitious Waterproofing

Cementitious waterproofing is probably the easiest method of waterproofing a building since it’s easy to mix and apply.

Cementitious waterproofing coatings are breathable, seamless coatings, providing positive and negative side waterproofing protection on concrete and masonry surfaces. They prevent damage from water infiltration and resist mold and mildew.

Cementitious waterproofing is applied as a slurry and acts as a damp proof membrane for brickwork, concrete or any cementitious substrate. A flexible waterproof coating for use where vibration or cracking is anticipated.

Typical applications of cementitious waterproofing are basements, cellars, toilets, showers, wet rooms and other internal wet areas. Ponds, water features and concrete tank waterproofing are some of the outdoor jobs that can be done.

Liquid Applied Membrane

Liquid Applied Membrane (LAM) is a monolithic, fully-bonded, liquid-based coating used for many waterproofing and roofing applications. The liquid coating cures forming a rubber-like waterproof membrane and can be used on asphalt, bitumen, concrete and similar substrates.

Typical applications include waterproofing roofs, flat roofs, basements, terraces, wet rooms, tanks etc. Apply to bitumen, brick, concrete, stone, metal, wood, fiber cement etc.

Bituminous Membrane

A bituminous membrane is a type of roofing system for buildings used to create a watertight roof made from modified bitumen usually comprising of two layers. Other types of membrane roofs are made from synthetic rubber, PVC or thermoplastic.

Bituminous membranes are good for waterproofing roofs, flat roofs, basements, cellars and similar structures.

Bituminous Coating

Bituminous coatings are used to build a waterproof and flexible protective coat for waterproofing under water structures, steel work weather protection, concrete foundations, waterproofing wood, concrete and potable water tanks.

Bituminous coatings are made of bitumen or coal tar which is dissolved in mineral spirit or naphtha. Bitumen is also known as asphalt which is sticky, black, and highly viscous liquid or semi-solid form of petroleum. Natural bitumen is found in deposits of oil sands and pitch lakes, whilst refined bitumen is gleaned from the distillation of crude oil.

Polyurethane Liquid Membrane

Polyurethane Liquid Membrane is a cold applied, odour free waterproofing solution for refurbishment of old buildings and new builds.

A big advantage of Polyurethane Liquid Membrane coating is, unlike conventional roofing systems, it forms a seamless membrane on the roof and is able to waterproof round details easily. Once applied typical cure times are about 24 hours.

Polyurethane Liquid Membrane coating is typically used to waterproof flat roofs, pitched roofing, metal cladding, car parks, gutters, vents, pipes, rainwater outlets, parapet walls, rooflights, heating, ventilation, air conditioning and ducting.

What are Type A, Type B and Type C waterproofing?

BS 8102: 2009 ‘Code of Practice for the Protection of Below Ground Structures Against Water from the Ground’ is the British Standard which gives recommendations and provides guidance on methods of dealing with and preventing the entry of water from surrounding ground into a structure at below ground level. It defines three types of waterproofing products – Type A, Type B and Type C.

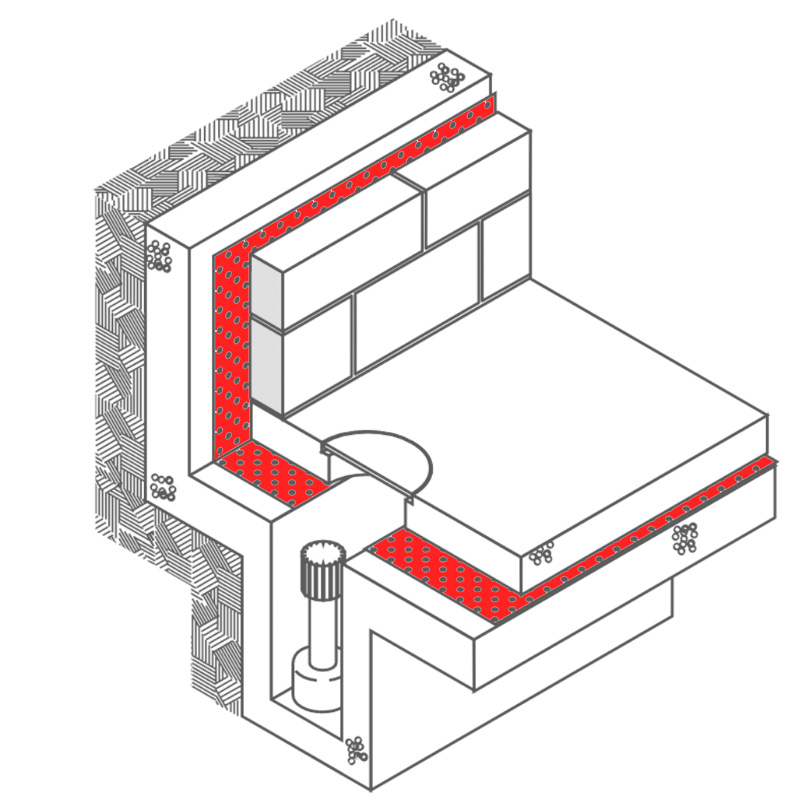

Type A (Barrier) Protection

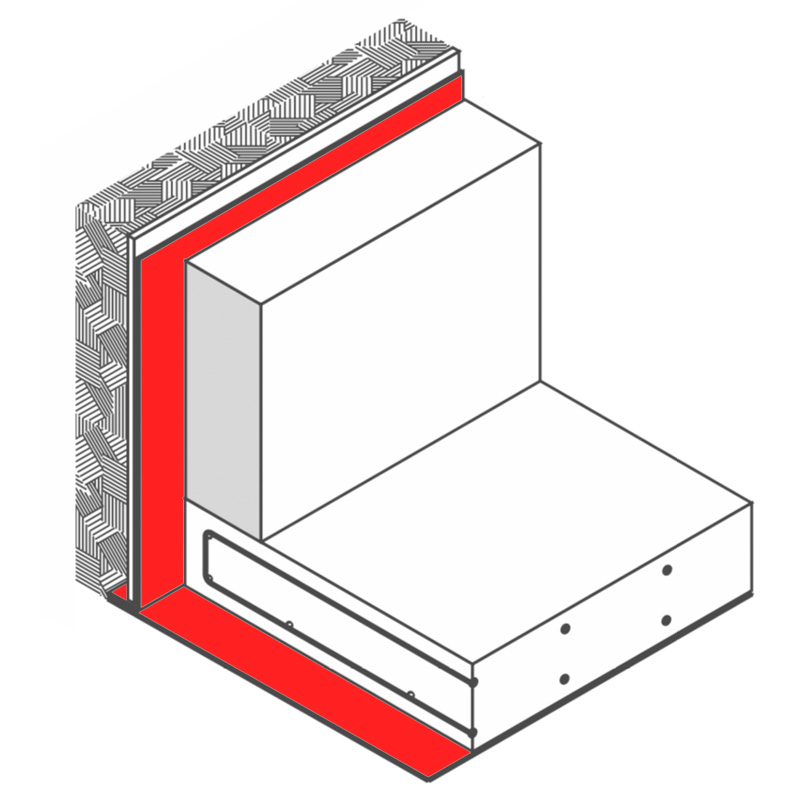

Type A Protection is often referred to as Tanking, which provides protection against ground water ingress by applying waterproof material to the internal or external walls and floor of a basement or cellar to form a barrier between the structure and any groundwater present.

Typical examples: basement renovations, cellar refurbishments, new build basements, storage rooms, utility rooms, underground car parks, earth retaining walls

Type B (Structurally Integral)

Type B Protection uses the structure itself against water ingress, Type B relies on the design and materials decided at the waterproofing design stage and integrated during construction. Design, materials and quality of workmanship are factors contributing to its success. Construction joints are the most at risk and likely source of any leaks.

Typical examples: reinforced concrete, new build basements, new build cellars.

Type C (Drained) Protection

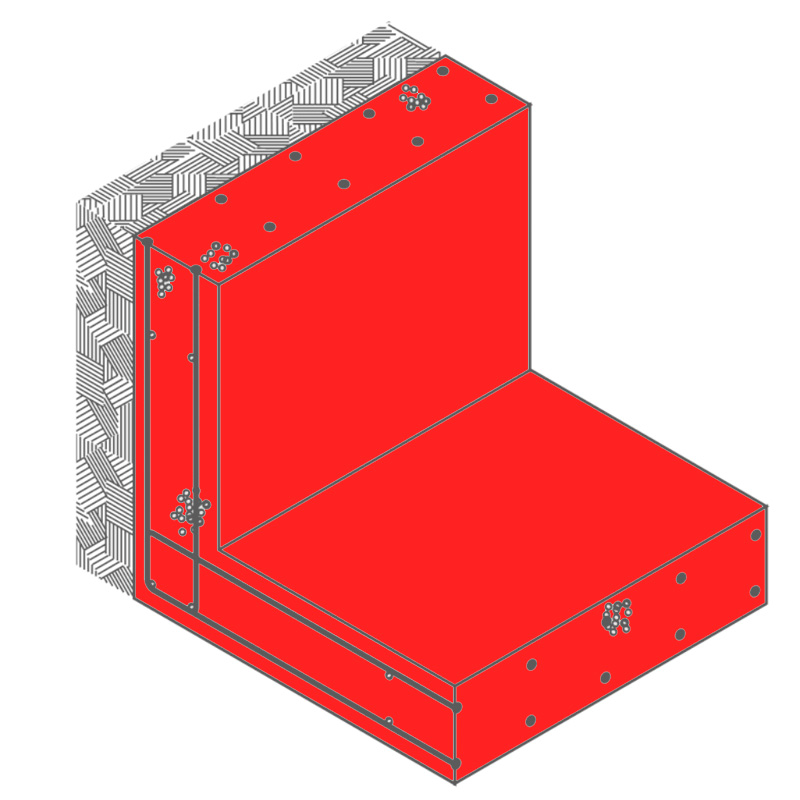

Type C Protection is provided by an internal water management system, allowing moisture or running water to pass through the external wall or floor of the structure and to the cavity between the external shell and internal cavity drainage membrane.

The water is collected via the Cavity Drain Membrane and then diverted into a controlled drainage system. Water is then diverted into a designated safe point of disposal such as a sump or pump chamber or away from the structure.

Typical examples: basement and cellar conversions, utility rooms, garages, car parks, earth retaining walls.